Itoya Preservation Upgrade Kit — Test Report

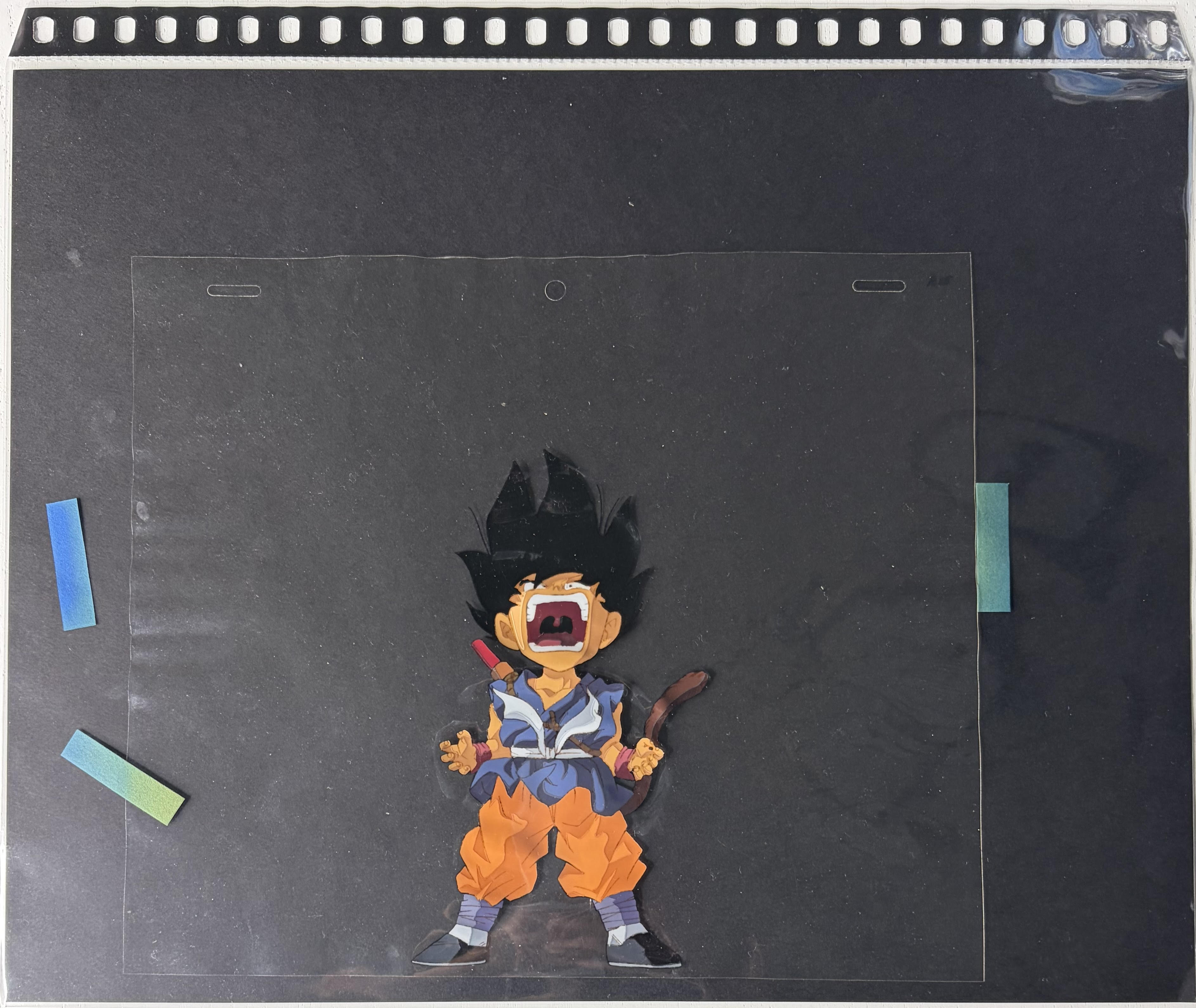

Bench tests validating the Cel Nexus preservation insert as an acetic‑acid sink for low‑emission storage, and documenting the boundary‑layer limitation that defines the intended use case.

Summary

| Test | Scenario | Primary Outcome | What it proves | |

|---|---|---|---|---|

| 1 | Jar — 24-hour emission suppression |

Cel coupons known emitter: 1–2 ppm / 24 hr (AD Level 1) Duration: 24 hours |

Control: ~1 ppm @ 24 hr; A-D strip green With insert: no measurable ppm; A-D strip blue |

Confirms the insert acts as an effective sink in short-duration, low-ppm conditions within the intended operating band. |

| 2 | Jar — long-duration stability |

Cel coupons low emitter: <0.5 ppm / 24 hr (trace measurable acid) Duration: 24 days |

Control: strip green by ~36 hr; 0.5–1 ppm @ day 24; strip green With insert: no measurable ppm @ day 24; strip blue |

Demonstrates durable performance over long duration in a low emission regime, maintaining a clean sleeve atmosphere without measurable accumulation. |

| 3 | PolyGlass sleeve — stress test (boundary-layer limit) |

Highly acidic / high-emission cel (intentionally beyond operating range) Duration: 48 hours |

Control: boundary layer strip yellow; outer strips show green hues With insert: boundary layer strip yellow; surrounding strips blue |

Defines the limitation: the sink reduces environmental spread, but cannot prevent boundary-layer accumulation under high emission. |

| 4 | PolyGlass sleeve — validation at upper operating range |

Slower emitter: 1–2 ppm range (upper end of intended band) Duration: 3 days |

Control: boundary layer strip green; far strips bluish; near strips green-tinted With insert: boundary layer improved (green but less); environmental strips clean blue |

Confirms intended performance in the real sleeve geometry: improves boundary-layer severity and prevents environmental buildup for Level 0–1 storage. |

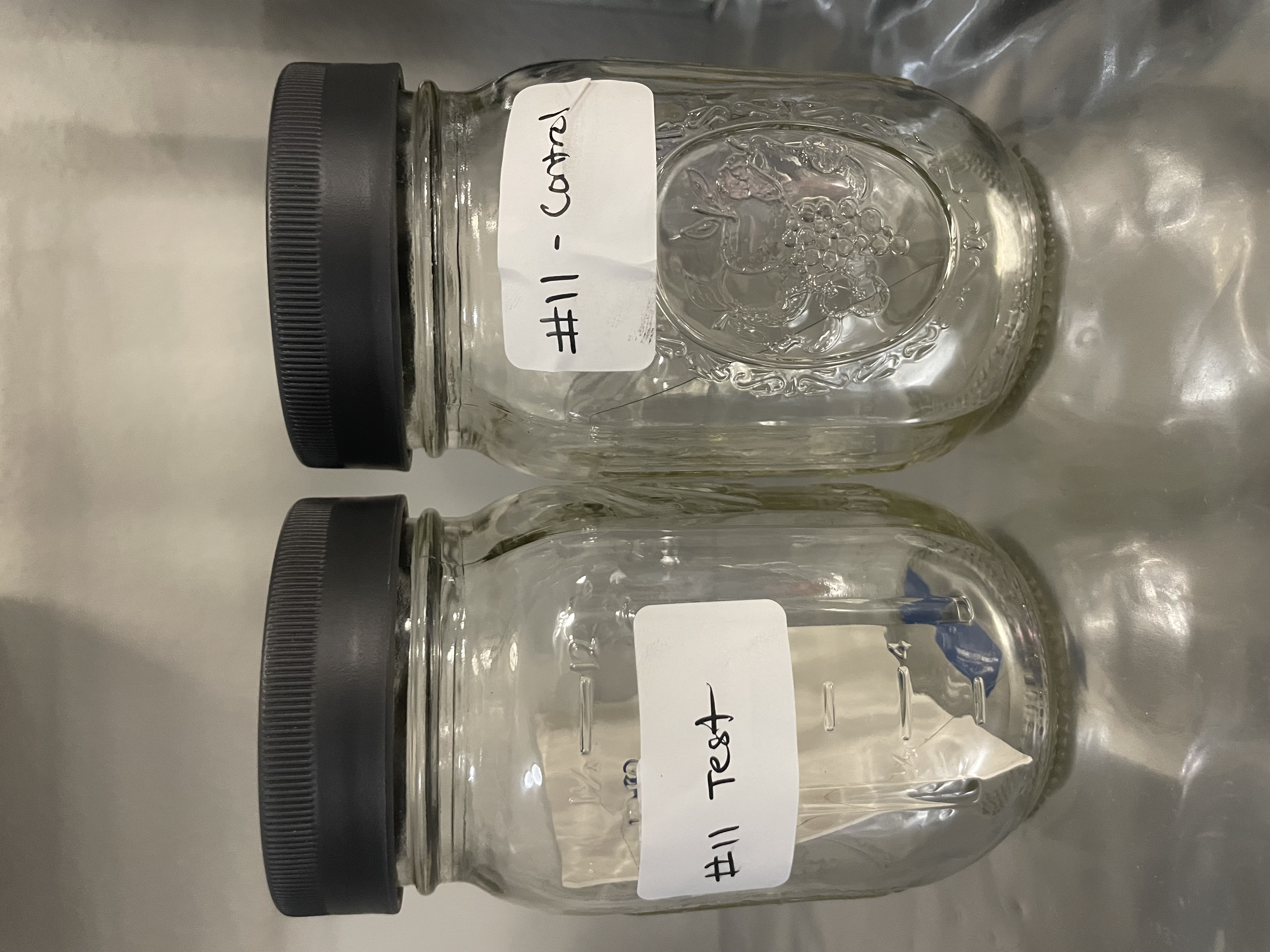

Test 1 — 24‑Hour Emission Suppression (Jar)

Results

This was a 24-hour sealed jar test using cellulose acetate coupons known to emit in the 1–2 ppm / 24 hr range (A-D Level 1).

- Control (no insert): ~1 ppm measured after 24 hours; A-D strip shifted green.

- With Preservation Insert: no measurable ppm after 24 hours; A-D strip remained blue.

Interpretation

Under short-duration, low-ppm emission conditions representative of early vinegar syndrome, the preservation insert prevented measurable vapor-phase acetic acid accumulation. This validates that the insert functions as an effective sink within the intended operating band (Level 0–1).

Test 2 — 24‑Day Stability (Jar)

Results

This test used the same sealed jar geometry as Test 1, but with a known low emitter (typically <0.5 ppm over 24 hours, with trace measurable acid).

- 24 hours: Test strip remained blue while the control strip turned green in ~36 hours.

- 24 days (end of test): Control measured between 0.5–1 ppm; test showed no measurable ppm.

- Strip colors at day 24: Control green; test blue.

Interpretation

This validates long-duration performance in a low emission regime. Even over 24 days, the insert prevented measurable accumulation and maintained a clean vapor environment, demonstrating durability in realistic long-term storage conditions for low-emission cels.

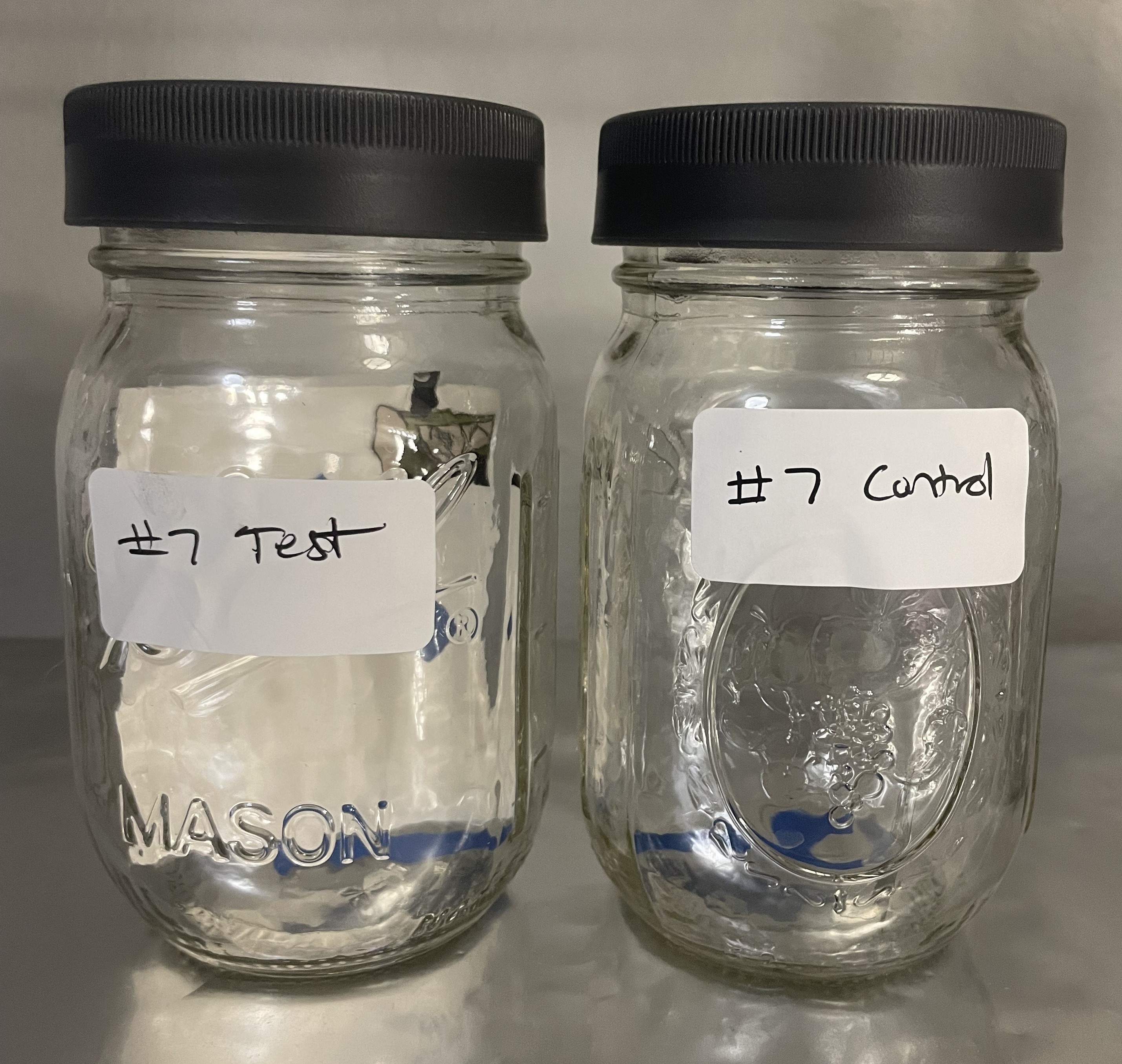

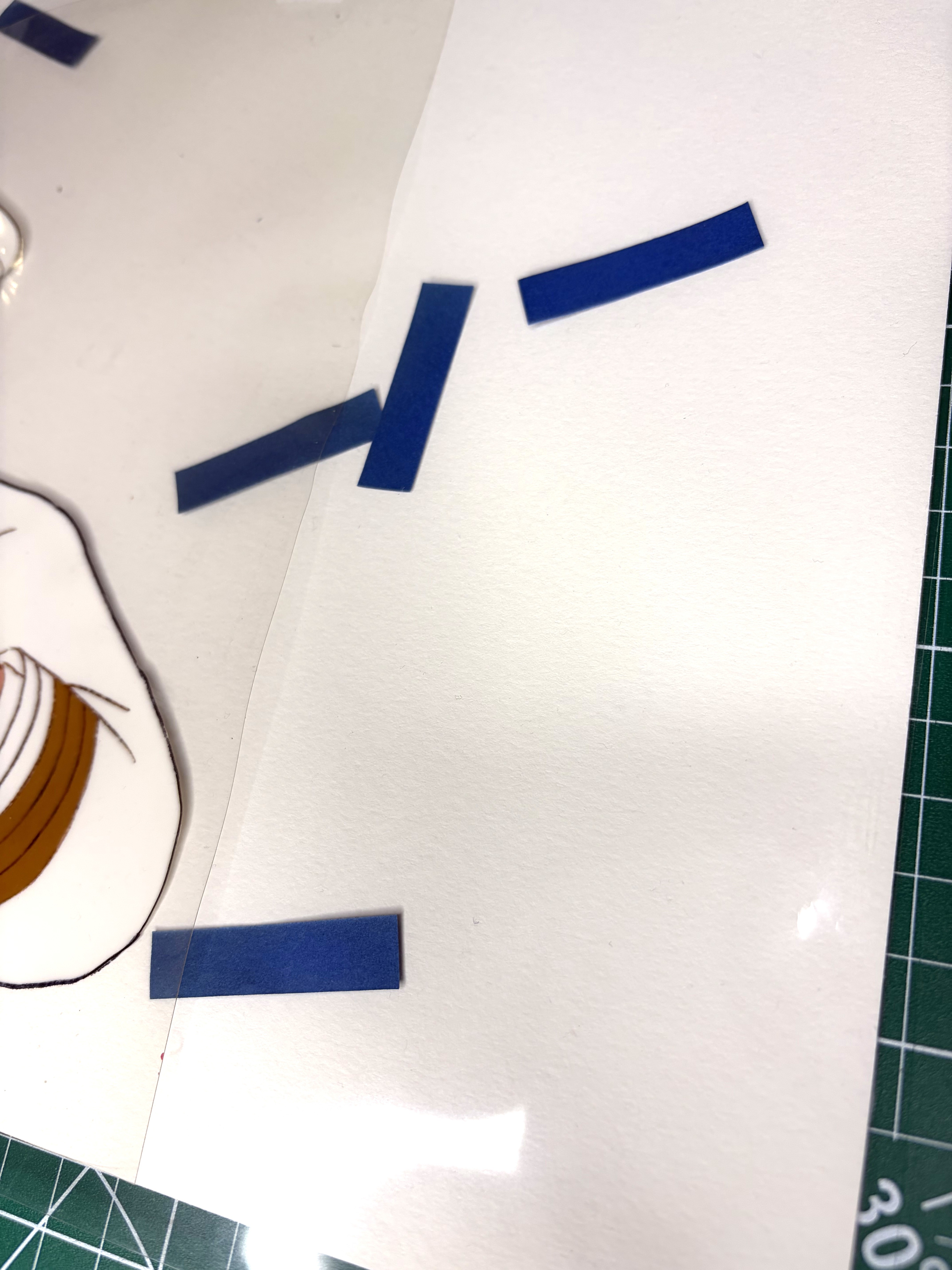

Test 3 — PolyGlass Sleeve Stress Test (Boundary‑Layer Limit)

Setup

A highly acidic, high-emission cel was placed in standard PolyGlass sleeve geometry in two configurations:

- Control: PolyGlass sleeve with black acid-free paper.

- Test: PolyGlass sleeve with the Cel Nexus preservation insert.

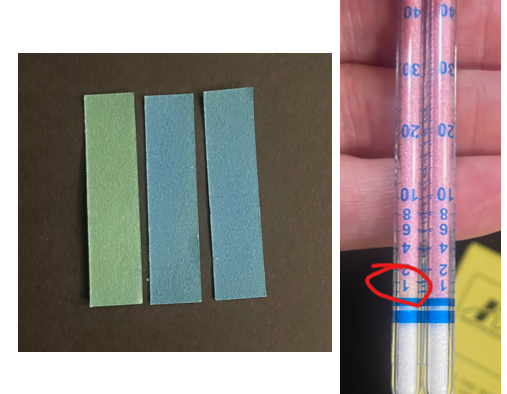

Results (48 hours)

- Control: boundary layer strip turned yellow; strips outside the cel showed green hues within the sleeve volume.

- With insert: boundary layer strip also turned yellow, but surrounding environmental strips remained blue.

Interpretation

Under high emission, acetic acid can accumulate in the cel boundary layer faster than the sink can remove it. The insert still reduces environmental spread, but it is not designed to prevent boundary-layer accumulation in high-emission scenarios. This test defines the upper limit and explains the intended use case (Level 0–1).

Test 4 — PolyGlass Sleeve Validation (Low‑Emitter, Planned)

Same PolyGlass sleeve geometry as Test 3, but using a slower emitter in the 1–2 ppm range (upper end of intended operating band). The purpose is to validate performance in realistic sleeve geometry at the top end of the product’s operating range.

Results (3 days)

- Control: boundary layer strip turned green. Strips furthest from the cel were bluish, while strips closer to the cel showed green-tinted hues.

- With insert: boundary layer strip showed improvement (still green, but reduced intensity), and environmental strips remained clean blue.

Interpretation

This validates performance at the upper end of the intended use case. While sleeve geometry can still produce localized boundary-layer accumulation, the insert reduces the severity and prevents measurable environmental buildup, maintaining the overall sleeve atmosphere in the low-acid regime for AD Level 0–1 storage.

Notes for Readers

- “No measurable ppm” means below the practical resolution of the measurement method used in these runs.

- A‑D strip color is an integrated exposure indicator — it responds to both concentration and time.

- High‑emission behavior is a different regime; once autocatalysis is active, strategy shifts to rate control and containment.